OTLAV S.p.A produces and sells hinges for doors and windows and other accessories for frames.

Founded in 1956 by entrepreneur Angelo Padovan, Otlav has produced more than 2.2 billion of hinges since 1956.

Thanks to almost 100 filed patents, Otlav ensures high quality standards and is present with its wide range of products in more than 80 countries worldwide.

In 2007 the new headquarter in Santa Lucia di Piave became operative, created with excellent technologies and cutting-edge operational tools, it is a gem in the field of automation and allows cost reduction of both management and production.

MYRTUS: founded in 1990 in Maniago (PN) specialized in galvanic treatments.

SAMARCU: founded 2002 in Romania is focused on some high-tech producing processes.

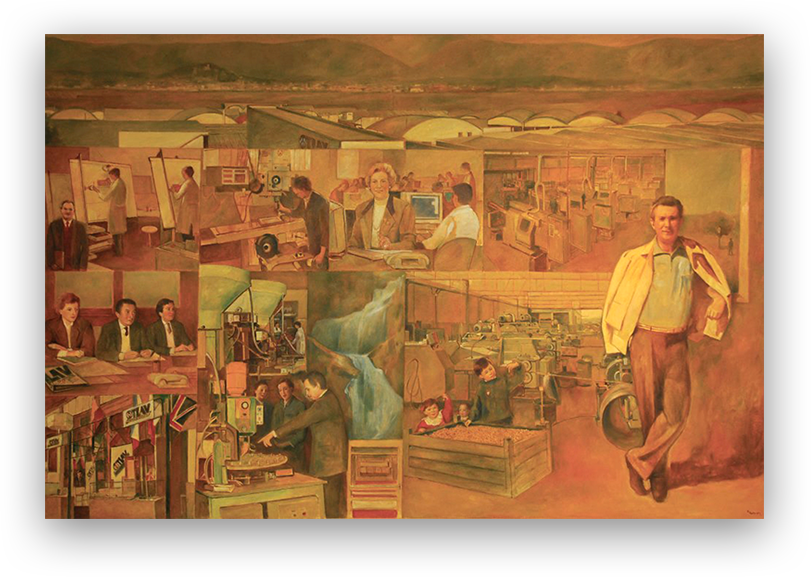

The workplace becomes an environment where lifetime is well spent and a space where each life leaves its unmistakable imprint and everything is always aligned with the highest degree of individual capacity. A single enthusiasm whose expression in a collective context identifies with a unique goal: to think, to act and to strive for progress.

Picture of the artist Giovanni Bisson from Santa Lucia depicting life scenes in Otlav, given to the owners by the workers in 1996. In the foreground right the founder Angelo Padovan

Automated and synchronized flow of both materials and information between the various departments of the company. Four years of research and projects have designed the perfect layout, above which the new plant was designed and built. This has raised the level of efficiency and has resulted in great reduction of management and production costs.

Latest lathes for producing items from 3 mm to 35 mm. Automatic issuing of XR cards to keep abreast of international quality standards.

OTLAV has developed an own technology to achieve outstanding results in production yields and quality. This is a vanguard department and every press is by now the heart of an island that brings together five(5) operating machines and allows to get in the production line real technological jewels.

Specific stage of processing that requires ancient knowledge of steel deformation and creep . It is only a fifty-years experience, combined with the passion of those who work in a stimulating environment, that is able to make the best out of such complex operations which would otherwise be impossible to deal with.

All the machineries are the result of over fifty years of know-how and unceasing improvement. All the machineries are designed and implemented within OTLAV by the appropriate and competent “Otlav Engineering Division.” These machines do not exist in the market and are the pride of dozens of technicians who have invested a substantial part of their lives in OTLAV.

Even the islands of this new department, with stations of up to eighteen robot positions, have all been designed and constructed entirely by "Otlav Engineering Division."

Department with injection presses of plastics coating materials having high technical characteristics aimed at specific needs.

Department with vertical presses of various tonnages, with complex subservient automatic machinery.

The recently opened new pressure casting workshop is equipped with the most modern facilities. Best quality standards and highest performances characterize the manufacturing of high-precision metal components.

It is the creative force which stands behind OTLAV’s complete autonomy and independence from external circumstances. All molds are made here; 75% of the machineries needed for production purposes are also manufactured here and it is here that all maintenance operations of both ordinary and extraordinary, both mechanical and electronic products are executed. This department is OTLAV’s flagship because it is the result of studies, analysis and experiences accumulated by employees of the company since 1956 and handed on from the oldest to the youngest ones, who are steadily immersed in the various departments to learn the “art” and keep alive OTLAV great technological tradition.

It is a highly automated multi-functional department with a high concentration and cooperation of various functions and technologies: stacker cranes which collect and store pallets and crates; shuttles loading and depositing materials at the various points of entry or exit of the “Automatic Material Handling” ring or towards shipping bays; the station for automatic proportioning of the containers ;the robotic station for the recognition and counting of parts in entry; the system of packaging and palletising the finished product; the equipped picking bays . The service of transporting materials through the warehouse,the production departments and the check-in or inspection area is ensured by automatic laser-guided carts or Laser Guided Vehicles (LGV). Everything is governed by an efficient management system which is integrated in the general computer system of the company.